This can occur during room temperature metal shaping processes such as bending, drawing, and rolling. Residual stresses arise when metal plastically deforms and the deformation is not uniform throughout the metal’s cross-section or along the length of the metal. Surface tensile residual pressures add to an applied tensile pressure, reducing resistance to fatigue and stress-corrosion cracking Non-uniform deformation Surface residual compressive pressure reduces the effects of applied tensile pressure, improving resistance to fatigue and stress-corrosion cracking. So, residual stresses can be harmful or beneficial, depending on whether the stress is tensile or compressive.įor fatigue and stress corrosion cracking, the stress at the surface of a component is important. Tensile residual stress adds to an applied tensile stress and compressive residual stress subtracts from an applied tensile stress. Effects of residual stressĬonsidering only applied and residual stresses, the total pressume on a metal is a sum of the applied stress and the residual stress. In many cases, tensile and compressive residual forces can co-exist within a component. Regardless of the origin, residual stress can be tensile or compressive. Phase transformations during heat treating.The deformation is associated with stretching of the bonds between a metal’s atoms. Elastic pressures are less than a metal’s yield strength and cause elastic deformation of the metal.

#Residual stress free

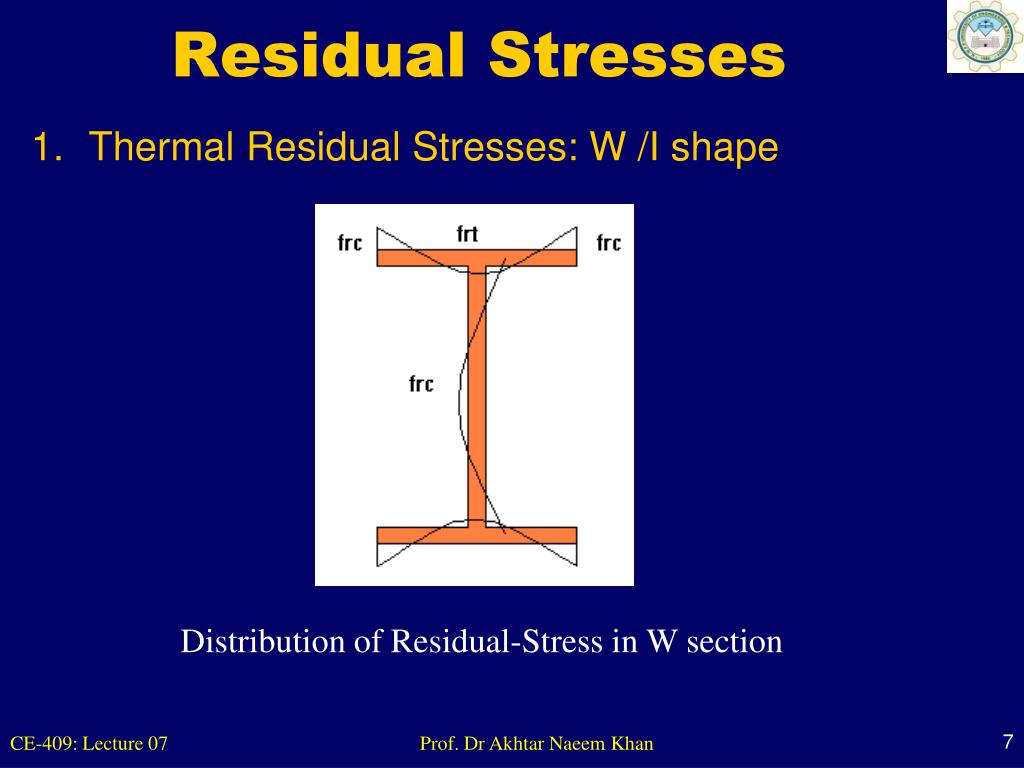

Residual stresses are locked-in elastic pressures present in a metal that is free of external forces. In fact, components sometimes fail due to stress corrosion cracking when residual stress is the only source of tensile stress. When residual presures are tensile they add to the applied tensile pressure, reducing the life of a component. Understanding residual pressure and its sources is important when making decisions about a component’s shape, features, alloy, and fabrication process.įatigue and stress corrosion cracking require the presence of tensile stresses on a component. It’s important to be cognizant of the residual stresses in the component. When designing components consider fatigue or stress corrosion cracking. Root Cause Analysis and the 8D Corrective Action Process course.An Introduction to Reliability Engineering.Reliability Analysis Methods online course.14 Ways to Acquire Reliability Engineering Knowledge.Innovative Thinking in Reliability and Durability.Equipment Risk and Reliability in Downhole Applications.Musings on Reliability and Maintenance Topics.Metals Engineering and Product Reliability.Product Development and Process Improvement.Rooted in Reliability: The Plant Performance Podcast.Please contact us for additional information. For example, we are experts at residual stress measurements and fatigue analysis accounting for residual stress effects. At Hill Engineering we work with residual stress on a daily basis. There are, of course, much more in-depth technical explanations that we can share with you as well. That’s a simple answer to the question of what is residual stress. But as we push for higher performing structures that operate closer to the cutting-edge of technology, factors like residual stress can be the difference between successful performance and structural failure. Often structures are designed with considerable safety factors and the effects of residual stresses can be ignored. For example, if the residual stresses are large the material will not be able to sustain as much applied stress.Īs engineers we care about residual stresses because they affect material performance. The applied and residual stresses combine together to determine the ultimate strength or performance of the material. Applied stresses arise when you pick up something heavy. Going back to our human body example, residual stress is the tightness that you feel in your shoulders while standing or sitting. We refer to these internal stresses as residual stresses because they exist within the material itself.Īpplied stresses develop when the material is loaded by outside forces. Just like with our bodies where we sometimes have tightness in our muscles, there are regions in materials that are under stress as they are pulled or pushed by the surrounding material. What is residual stress? In a very basic, non-technical sense residual stress is stress that is locked in a material during manufacturing. At Hill Engineering we love to talk about our work and we have a lot to share about residual stress. Many of our customers, friends, colleagues, and family members like to ask us questions about residual stress including: What is residual stress? How do you measure it? How does residual stress affect material performance? If you have questions about these topics, you’ve come to the right place.

What is residual stress? That’s a very common question when you work at Hill Engineering.

0 kommentar(er)

0 kommentar(er)